Spring Floors 101

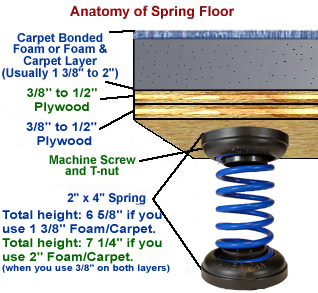

If you are considering the purchase of a Spring Floor for gymnastics, cheer, aerobics or some martial arts, there is some basic information you need to know to make sense of the assembly processes and terminology you will find. A great place to start is studying the diagram to the right. For Spring Floors for Martial Arts with vinyl covered mats visit here. |

|

|

Springs When comparing flooring systems, it's crucial to pay attention to the type of springs provided, as there can be variations. Our preferred choice is the American Power Spring™, shown on the left. It features a durable, oil-tempered 2" x 4" coil with plastic retainer caps (top and bottom) that ensure vertical alignment. Both the top and bottom caps are identical. We believe that the American Spring's coil has a preferable coating, and the caps have a more robust retention system. The spring comes with a t-nut, washer, and screw for attachment. The t-nuts are applied to 1/4" drilled holes on the top of the bottom boards. With American Power Springs, the caps, springs, and hardware are shipped together within a week. If you are considering another brand, inquire about how they will ship and the estimated timeline. The top caps are attached to 3/8" (or 9mm) to 1/2" Baltic Birch Plywood using a washer and screw secured into the t-nut. The springs fit snugly into the caps that are attached to the boards. The bottom caps of the springs are placed directly on the concrete. Typically, there is one spring per square foot of the floor. Some vendors offer floors with foam blocks instead of springs, or a combination of both. However, it's important to note that foam blocks tend to wear out and lose their height faster over time due to constant weight compared to springs. Therefore, for longevity, it is advisable to consider using springs. The top layer of the floor, usually 3/8" (or 9mm) Baltic Birch, is attached to the springs (often with hook and loop fasteners). These two layers are staggered to ensure a uniform response from the floor. It's worth mentioning that the wood decking, which is the most critical aspect in terms of the floor's life expectancy and performance, may not always be included in the kits offered. Therefore, make sure you have a clear understanding of what components are included in your purchase. |

|---|

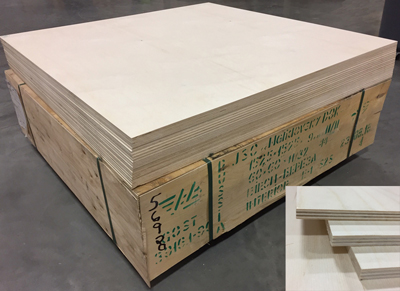

| Wood If you prefer, you have the option to purchase wood for your project from a local lumber yard such as Home Depot ®, Lowe's ®, or 84 Lumber ®. However, it's important to be cautious and consider the quality, thickness, and type of wood you choose, as they can significantly impact the outcome. Most reputable suppliers of quality spring floors utilize Baltic Birch (sometimes referred to as Russian Birch) as their preferred wood. If you have difficulty finding Baltic Birch, you can use 1/2" Fir Plywood as an alternative. It's worth noting that Oriented Strand Board (OSB) tends to be more prone to breaking, especially over time, and when used in thinner thicknesses that are necessary for engaging the springs. To find Baltic Birch, you may consider reaching out to a local cabinet manufacturer as they might be able to procure it for you. Alternatively, we can also provide Baltic Birch to you directly, but it might be more cost-effective to source it locally and avoid shipping charges. Using Baltic Birch will ensure superior strength and durability for your floor. However, if you decide to go thicker with the wood, keep in mind, the springs may be less likely to engage during activity, especially for lighter athletes. |  |

| You can purchase an Assembled Spring Floor, like those sold here, where the springs are already mounted on the optimal wood for spring floors. Some manufacturers offer floors in 4' x 8' panels, but most of the leaders in the field have gone to 5' x 5' panels, as we have. They are much easier to ship and handle. Of course, some of the panels will need to be cut to make any given size of floor. This we can do for you, so you just have to set them down in sequence in your facility - no tools are needed. You can also order just the wood and make the cuts yourself. |

To Top Off Your Spring Floor It is a remarkably durable product. Learn more about Carpet Bonded Foam or Flexi-Rolls®. They are currently available in nine colors. This is by far the most common spring floor covering in the US today. Many gyms and schools use it without a spring floor as well. It normally comes in 1 3/8" or 2" thicknesses. There is a 3/4" thick version available (in Carpet Bonded Foam only), but it is not intended for tumbling. EVA Enhanced versions of these rolls are also available in 1 3/4" or 2 1/4" thicknesses.

|

Carpet Bonded Foam (2" shown here) |

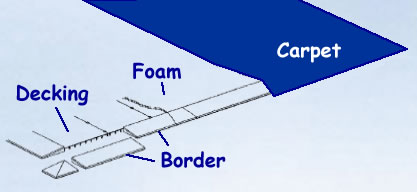

| If you go choose to go with foam and separate carpet, this is a more expensive way but makes for a more beautiful floor. The foam (usually Trocellen) is available in the same 1 1/4" or 1 7/8" thicknesses. There is also a EVA Enhanced Trocellen which is more expensive but has a better response. It usually comes in 1.5" or 2" thicknesses. The carpet is normally connected with velcro strips under the carpet. The carpet will come in 3 to 4 segments, depending on your overall floor size. There are many different colors of carpet available. The most readily available is Royal Blue. |  |

| If you choose the foam with a separate carpet option, tapered foam borders are an option for completing your floor. They allow a gradual transition to floor level (see right). Usually the angled border extends about 14" from the decking. This is the sharpest (and most expensive) of your options. This is top-of-the-line and is what you will see at all the major gymnastics competitions. You will need the velcro belts to attach to the carpet segments. These join the segments under the carpet. You will need to purchase the adhesive border tape to define the competition area. |

| If you are leaning toward going Carpet Bonded Foam or Flexi-Rolls®

to top-off your floor, you may consider using a Vinyl Floor Skirting. This product velcros to the top of your CBF around the perimeter and hangs to the floor, hiding the wood, springs, etc. and providing a nicer look. This is used to enhance the safety and appearance of the floor (no exposed wood or springs). It also prevents things from rolling under the flooring and prevents "dust bunny" habitats. Another option is Angled Carpet Bonded Border. You can check out this and other options on our Borders page. When you are shopping for a spring floor, read carefully what the provider offers. Some "Kits" come with just the springs or springs and velcro. Others will be wood, spring and hook and loop fasteners - but you will need to cut, drill and attach the springs. Dependent on size, a standard (42' x 42') spring floor will assemble in approximately 60 hours with instructions geared towards the booster club production line (this depends largely on how many workers you have). The most responsive Spring Floor are assembled layer to layer with velcro. This adds considerably to the time it takes to complete construction, but improves the uniformity of rebound and makes it far easier to move should that become necessary. To learn more about building your own floor, visit our Kits page. If you get an Assembled Spring Floor, you can cut the installation time to just an hour or so (depending on the size you choose). You also are assured that it is done right and is (in most cases) covered by a warranty. We think this is the way to go. Single Layer Systems A single layer floor will usually be made with 1/2" - 3/4" thick plywood and use H-channels and straps to lock the boards together. This floor is simple to take up and down, but the H-channels must follow a specific layout. Channels tend to move around, which is the downside. As a result, you will end up with soft spots over time as they shift out of place. Additionally, the straps can stretch and allow the floorboards to slowly shift. A single layer spring floor will not stay square over a period of time and gaps may form. Every so often, you may have to adjust the floor system and tighten the straps. What We Recommend For a flooring system, we recommend and provide are a dual layer 3/8" (or 9mm) Baltic (or Russian) Birch. (The American Gym is the largest single user of this material in the United States.) We have found it provides a lively, fast reliable and durable floor for tumblers from 60 to 200+ pounds. This also creates happy coaches. OSB, we have found, is a good product but does not supply the longevity of Baltic Birch and tends to break easily under the pressures your floor will encounter. We will be glad to furnish you with a price for your floor (or strip). Just let us know what you have in mind. We can produce any size. Just remember that the foam product required usually comes in 6' widths. So, you might want to keep one dimension divisible by 6 feet, where possible. |

All spring floors are not created equal. Though many manufacturers use the same or similar materials, the difference can be dramatic.

- Click here to see how we supply Assembled Spring Floors for Cheer, Gymnastics and Aerobics.

- See Spring Floors for Martial Arts!

Our Products

Your Cart

Your Account

Login Status

Login Status